THE HYDROPONICS PROJECT

Overview

Proposed project to sustainably produce healthy vegetables to support school feeding programs in Ghana using hydroponics.

Problem Statement

Malnutrition is one of the major problems facing developing countries, especially among children. It is estimated that 28% of children under the age of five years are stunted whilst 14% are underweight in Ghana [1]. Malnutrition in children is known to adversely affect the cognitive and mental development of children. The access to good nutrition, both at home and at schools, is essential and would contribute to elimination of malnutrition and all its associated health and developmental problems. In addition to addressing malnutrition, the school feeding programs can boost school enrollment and the retention of children in schools. Unfortunately due to inadequate funding and limited supply of nutritious vegetables for the Ghana School Feeding Program(GSFP), children are still not receiving the nutritious food they need in school.

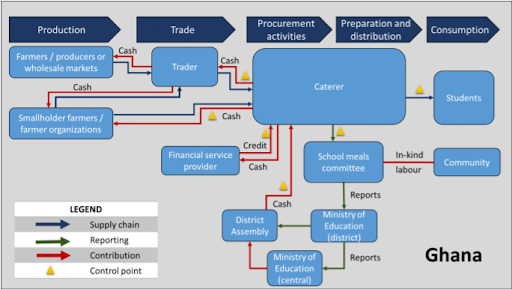

GSFP is one of the main interventions used to address hunger and malnutrition of school children in Ghana. The goal of the GSFP is to provide children in public school one hot nutritious meal per day, using locally grown food produce. The long term objective of the programme is to contribute to poverty reduction and food security in Ghana, while the immediate objective is to reduce hunger and malnutrition, boost domestic food production and increase school enrollment, attendance and retention [2].

The GSFP operates by giving contracts to caterers in local communities to source locally grown food from the local farmers and cook food for the public schools. Unfortunately the GSFP has numerous challenges ranging from poor sanitation, low quality of food served, and delays in paying caterers [3]. Due to the inconsistent and inadequate funding from the government, the contracted caterers are unable to receive the appropriate compensation of their services in time, forcing them to cut corners and thereby compromising on the quality of food being fed to school children. During periods of delayed funding the caterers are unable to source nutritious crops, vegetables and fruit for the school feeding program.

Supply Chain for Ghana’s Decentralized Operations Model [2]

To address this challenge of limited and inconsistent supply of nutritious vegetables we propose a school hydroponics project to produce nutritious healthy leafy greens all year round to supplement food supply for the GFSP. The school hydroponics project aims to supplement caterers with a fixed amount of nutritious leafy greens every week to help increase the nutrition content of food made for school children.

In Zambia, the World Food Program (WFP), in conjunction with the government, set up 23 greenhouses and hydroponic farms in schools. The program, aimed at promoting sustainable food production and supporting school feeding programs. The program trained over 400 teachers, parents, and students [4]. Residents of the surrounding community reported having access to fresher vegetables as well as experiencing relatively faster plant growth after the project. This Zambian program is the model for the hydroponics-supported school feeding project we wish to pilot in Ghana.

School hydroponics farm in Zambia [4]

Pilot Project Goals

1. To supplement the school feeding program with healthy vegetables (cabbage). Upon successful completion of the project, the school should be able to harvest 30 heads of cabbage per week from the hydroponics farms.

2. To educate students on the benefits of sustainable food production methods ie. hydroponics. Students will also learn how to create and maintain hydroponics systems.

Specifications

Hydroponics Design

This project uses a Nutrient Film Technique (NFT)/ hydroponics system to produce leafy vegetables. The main container will consist of 4-inch-diameter PVC pipes (a) laid out in 3 layers (top, middle, bottom) and connected to 3-inch-wide net pots (b) to hold the plants. Each 4-inch PVC pipe will have 15 plant sites, with the center of each site being 8 inches from the next. 4-inch PVC pipes on the same level will be separated by 8 inches. All the PVC pipes will be connected together with ¾-inch pipes (c). 4 flow valves (d) will be used to control the flow of water between the reservoir, the top layer, the middle layer, and the bottom layer. A submissive pump connected to a timer will pump nutritious water at regular time intervals through the system. Each hydroponics farm will have 180 plant sites to grow cabbage heads.

Vegetable Production (Cabbage)

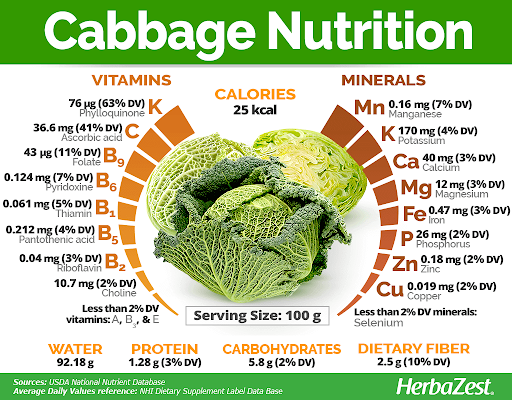

Based on research conducted with contracted GSFP caterers in Ghana, cabbage is one of the most commonly consumed vegetables in public schools, eaten alongside staple food like rice and yams. We expect the hydroponics systems to produce 30 heads of fully grown cabbage per week when fully implemented. Cabbage is very nutritious and contains a lot of vitamins, minerals and proteins to help with children’s growth and cognitive development. Most importantly cabbage can be successfully grown in a hydroponic system. Please find below images of cabbage being grown in hydroponics.

Nutrition Content of Cabbage [5]

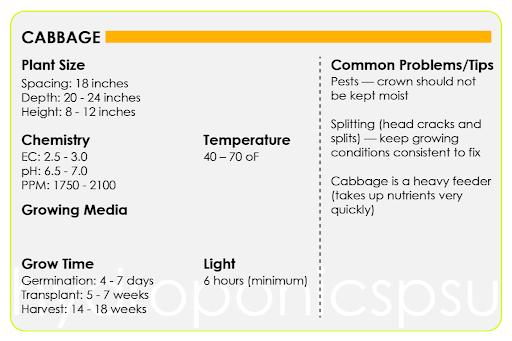

Requirements to grow Cabbage in Hydroponics [9]

Cabbage grown in NFT Hydroponic System [6]

Pilot Budget

Estimated cost to develop and run a pilot study of the school hydroponics system is roughly $8,000. $3,000 will go towards sourcing materials for the constructing three hydroponic farms with 540 plant sites, $1,500 towards creating a protective growing environment for the farms and another $1,500 towards catering to supplies and maintenance. Finally, $1,000 will be set aside for emergency funding and unforeseen costs, and another $1,000 for the project management.

Budget Allocation |

|

| Project Management | $1,000 |

| Material for Construction | $3,000 |

| Supplies and Maintenance | $1,500 |

| Protective Container | $2,500 |

| Emergency Funds | $1,000 |

| Total | $9,000 |

Materials for Construction |

Unit |

Price per Unite ($) |

Total price ($) |

Shop |

| 4in Dia x 10ft PVC Pipe | 12 | 18.45 | 221.4 | link |

| 4in Dia end cap | 25 | 2.48 | 62 | link |

| 3/4in Tee PVC fitting | 20 | 0.78 | 15.6 | link |

| 3/4in Dia x 10ft PVC pipe | 10 | 3.83 | 38.3 | link |

| 3/4in Dia Elbow PVC fitting | 20 | 0.6 | 12 | link |

| 3/4in Ball Valve | 15 | 2.98 | 44.7 | link |

| 3in net pot (25 in 1) | 8 | 16.99 | 135.92 | link |

| 2in net pot (40 in 1) | 0 | 12.99 | 0 | link |

| Submissive pump | 1 | 21.32 | 21.32 | link |

| Nutrient Reservoir (60 gallon) | 1 | 49.98 | 49.98 | link |

| Pump timer | 1 | 14.99 | 14.99 | link |

| Growing light | 18 | 9.98 | 179.64 | link |

| PVC Glue | 1 | 9.64 | 9.64 | link |

| Growing medium (28 in 1) | 7 | 8.95 | 62.65 | link |

| Growing medium (Pebbles) | 3 | 13.95 | 41.85 | link |

| PH Control kit | 2 | 20.05 | 40.1 | link |

| Nutrients | 2 | 15.99 | 31.98 | link |

| Total | 982.07 |

Cost of Materials needed to build each hydroponic farm (~$1,000)

Risk and Mitigation Strategies

The major challenges involved in this project are unstable power supply and locals’ initial inadequate knowledge of hydroponic systems.

Unstable power supply is a risk as the school is connected to the national grid which does not supply constant power. Power outages can turn off the pump and interrupt nutrient solution supply throughout the system. To mitigate this risk, the hydroponics system has been designed as a deep water culture system [7]. Deep water culture systems ensure constant water supply to growing containers even with temporarily disabled pumps. Power outages can also interrupt with the growing lights for the farm. To mitigate this power supply risk we may consider investing in solar and battery technologies to reduce the overreliance on the national power grid for electricity.

Maintaining a hydroponics system can be knowledge and time-intensive. Water pH and nutrient levels need to be closely monitored and adjusted to meet the plants’ requirements. Plant growth needs to be constantly checked as well. To mitigate the maintenance and management risk for this pilot study, we will grow cabbage, a plant that requires minimal water pH and nutrient adjustments. We will also provide locals with an information card with simplified directions on how to grow cabbage using hydroponics. Poor sanitation and maintenance of the hydroponics system can result in total failure of all crops. Water borne disease can spread very quickly and easily in a hydroponics farm. To mitigate risk, the teacher staff and the students will have quick training on proper management of the hydroponic system. The teacher staff and students managing the farm will be given direct access to an expert to ask questions throughout the period of the pilot study.

Finally, another challenge that could affect the project is burglary. Both the components and produce from the project are liable to theft. The hydroponic farms will be enclosed inside a shipping container. This container would also protect the system from possible damage by adverse weather conditions. The image below shows an example of a hydroponic farm inside a shipping container.

Hydroponic farm inside a shipping Container (link)

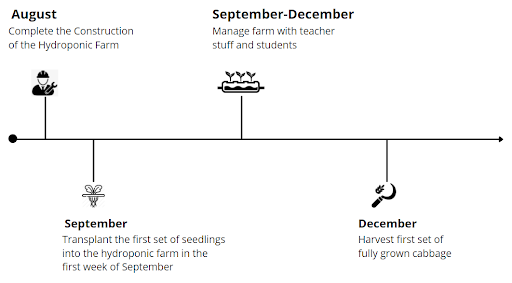

Pilot Timeline

The goal is to construct the farm in August, and begin transplanting into the hydroponic farm in September. If all goes well we should begin and continue to harvest from December. In order to ensure that we can harvest 30 heads of cabbage per week from the farm, 30 seedlings of cabbage will be transplanted into the farm per week starting in september.

Value Proposition

This project could serve as an investment in the Ghana school feeding system.

Once functional, the pilot hydroponic farms should produce 30 heads of healthy cabbage per week. The average price of cabbage is about $3 in Ghana [8], therefore the farm could help schools save up to $360 in monthly food expenditure. Furthermore, this estimate indicates that the hydroponic farm could recoup its initial implementation cost in approximately two years ceteris paribus.

This project could also provide a hydroponics learning hub for students. The students would be encouraged to monitor and maintain hydroponics systems. In the long run, students could reproduce these systems in their homes and communities as demonstrated by the WFP pilot study in Zambia [4].

Personnel

Edward Amoah, the project lead, has prior experience designing hydroponics systems. Amoah was involved in Penn State University (PSU) hydroponics projects, working alongside other students to design and build open-source hydroponics systems using recycled two-liter bottles. Amoah also has experience leading international projects. In the 2020 PSU Nittany AI challenge, Amoah led a global team of eight to build the education-based venture Nyansapo. Nyansapo is an app that has helped instructors teach over 200 children in Kenya using the Teaching at the Right Level (TaRL) educational approach.

Andrews Idun will act as the Ghana project liaison and manager. Mr. Idun is a professional teacher with eight years’ experience in school management. As the Founder and Executive Director of TOPA Ghana, an NGO that facilitates community development, Mr. Idun fosters communal advancement through business and entrepreneurial training. Mr. Idun is also a Young African Leaders Initiative (YALI) Network Alumnus and Thought for Food (TFF) Ambassador. As such, he promotes food security programs and encourages agribusiness among the youth. Mr. Idun will coordinate all management activities for the project in Ghana and ensure that the project runs smoothly with the government and school administration.

Acting as project advisors will be Dr. Alexander Wireko and Mr. Bimpong. Dr. Wireko is a Crop and Soil Science Professor from Kwame Nkrumah University of Science and Technology (KNUST). Mr. Bimpong is the Headteacher of Kwadaso/Asuoyeboah S. D. A Primary ‘B’ School. Both have provided this project with an official letter of support. Mr. Bimpong has officially agreed to provide this project with space inside his school to support the pilot study. Dr. Wireko has committed to support the project with his expertise and oversight. A copy of the letters of support and pictures of the school are contained in the appendix.

Appendix

Proposed pilot site: Kwadaso/Asuoyeboah Primary School

Entrance of Kwadaso/Asuoyeboah S. D. A Primary ‘B’ School

References

[1] Emmanuel, K. (2013). Assessment of the Nutritional Status of Junior High School Students – Evidence from Mfantseman Municipality of Ghana. Science Journal of Public Health, 1(5), 222. https://doi.org/10.11648/j.sjph.20130105.16

[2] https://docs.wfp.org/api/documents/WFP-0000105577/download/

[3]https://www.ghanaweb.com/GhanaHomePage/NewsArchive/School-feeding-program-is-a-mess-298982

[4]https://www.wfp.org/stories/african-school-feeding-day-hydroponics-school-meals-zambia-nutrition

[5] https://www.herbazest.com/herbs/cabbage

[6] https://www.pinterest.com/pin/166140673728388029/

[7]https://www.gardeningknowhow.com/special/containers/deep-water-culture-for-plants.htm